Recycling : Revolutionizing refrigerator recycling with PMR

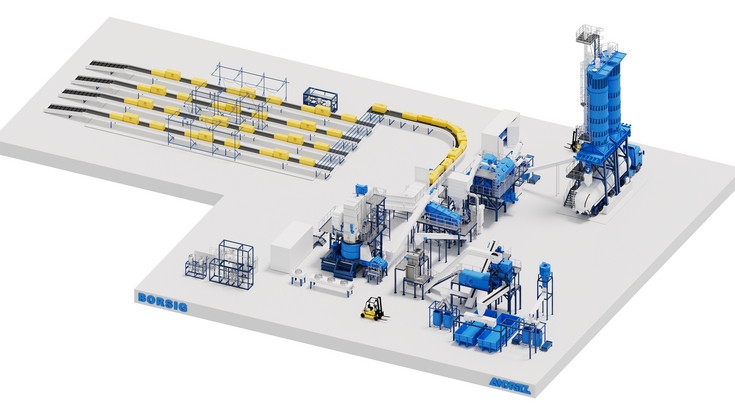

Refrigerator recycling Systems ANDRITZ – BORSIG

- © AndritzWorking together, the companies have developed a new propellant recovery unit, which has several benefits for recycling plant operators, particularly in terms of cost and ease of maintenance.

The collaboration resulted in the Propellant Membrane Recovery (PMR), an innovative system with proven membrane gas process for safe, efficient, and reliable recovery and significantly improved lower OPEX structure.

Propellants, such as Pentanes and halogenated hydrocarbons (CFC) are indispensable propellants applied for insulating foams on refrigerators.

However, since these propellants are environmentally harmful greenhouse gases, the appliances must be disposed of responsibly and in accordance with environmental regulations. The relevant specifications and guidelines as well as the limit values for released propellant are set out in WEEELABEX.

During shredding, the propellants are released to the system’s gas phase. To maintain a non-hazardous atmosphere, Nitrogen is introduced as an inert gas. The corresponding gas mixture needs to be treated prior to exposure to the atmosphere.

When it is introduced into the PMR process unit, the process gas is directed to an oil-injected screw-type compression system that is operated at a discharge pressure of approx. 12 bar(a).

The gas/vapor is routed to the condensation skid and cooled down to 10-15 °C, which liquifies a significant portion of propellant and water. The condensate is fed into a decanter, from where the aqueous phase is routed to a waste water collector tank and the propellant to a barrel-filling station. Residual, noncondensable gas (mainly Nitrogen) / vapor (propellant) portion is fed to the membrane stage. Driven by a partial pressure difference, the propellant is passing the membrane, while the Nitrogen remains on the upper side. This permeated gas is routed to the inlet of gas compressor. Consequently, this recirculation raises the dew point of propellant for efficient liquification during cooling in main condenser.

On the membrane’s upstream outlet, pre-cleaned residual exhaust gas is routed to activated carbon type pressure swing adsorption (PSA) for final purification. Before venting to the environment, a certain portion of cleaned gas can be diverted and returned to QZ shredder for re-use. In the PSA unit, one adsorber vessel is in operation for removing residual HC traces, whereas the second installed adsorber is in regeneration under low pressure returning the captured propellant to compressor suction. Both adsorbers are connected to a changeover valve combination, allowing operation / regeneration in a defined time cycle. The cooling is achieved by a free air-cooled system combined with a chiller unit, using a closed loop.

For more information on our recycling technologies, please contact us or visit our homepage.