Case Study : Efficient Waste Management with LiDAR Technology

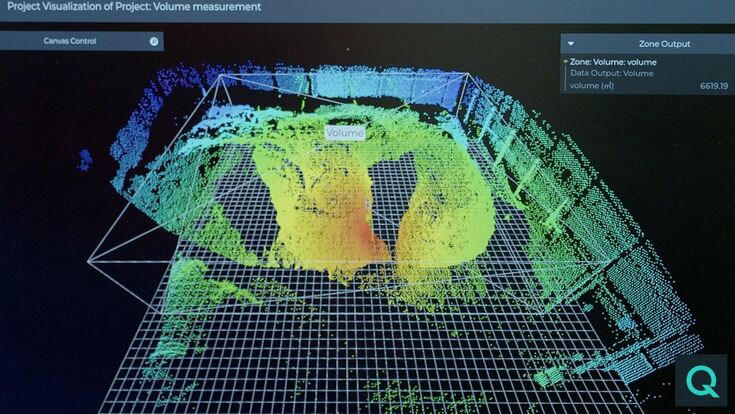

Point cloud of the waste piles in the hall. The LiDAR sensor calculates the inventory volume very accurately through a surface scan.

- © BlickfeldLevenseat, a Scottish resource management company operating since 1985, faced a challenge: one of their waste treatment and energy generation facilities for municipal waste covers nearly 3,000 square meters, and the materials delivered for sorting are constantly in motion. As a result, the previously employed methods, primarily visual estimation upon delivery and counting of incoming trucks, were inadequate for accurately determining inventory levels. This led to adverse effects in various areas.

Low Efficiency and Heightened Safety Concerns

The lack of inventory information resulted in inefficient processes and made operations vulnerable to disruptions. For example, when material accumulated too much in the storage facility due to process delays, such as outages, safety risks increased. The larger volume of waste heightened the risk of fires, pushed storage capacity to its limits, and necessitated the diversion of trucks to other locations, negatively impacting logistical efficiency.

Conversely, at times, underutilization of storage space resulted in missed opportunities. Available processing resources were not fully utilized, leading to lower production levels than could have been achieved, ultimately reflected in the numbers.

Therefore, a more accurate technology for inventory tracking needed to be identified and implemented.

The Solution: Inventory Tracking with LiDAR

The choice was made for a Volume Monitoring solution from the Munich-based LiDAR manufacturer Blickfeld, installed by Quvo, Blickfeld's exclusive partner for the waste and recycling industry in the UK and Northern Ireland. The Blickfeld solution is based on LiDAR technology ("Light Detection and Ranging") and provides real-time material data. This works by LiDAR sensors emitting several hundred thousand laser pulses per second across a large field of view, systematically scanning the surroundings. From this, 3D surface images are created, and a perception software accurately calculates the volume.

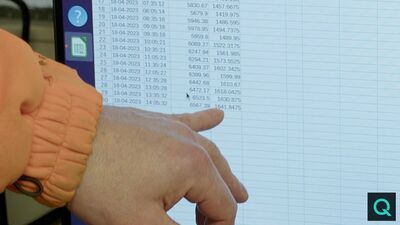

Despite the enormous dimensions of the facility, only four Blickfeld LiDAR sensors, model "Cube 1", mounted on the ceiling are sufficient to collect the data. This data is then made accessible to the employees via user-friendly dashboards.

Conclusion: More Efficient Processes and Reduced Safety Risks

Thanks to the LiDAR-based inventory tracking, Levenseat was able to increase efficiency in the storage area and logistics processes. Workflows are now smoother, truck scheduling is more precise, processing machine utilization has been optimized, and processing delays have been minimized.

Furthermore, Levenseat is now capable of proactively addressing safety risks, such as an increased fire hazard due to facility overcrowding. Due to these advantages, which quickly became evident after the installation in the first facility, there are already plans for further implementations of LiDAR technology. Levenseat is already working on equipping a second location, with more to follow.