Superworms munch through plastic : Encymatic Recycling: A gut feeling

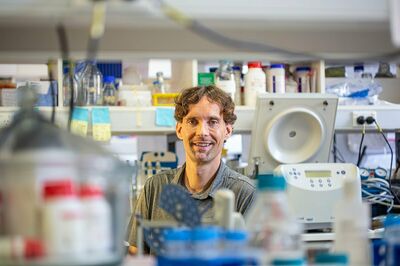

Encymatic recycling - using enzymes to break down plastics - seems one of the most promising candidates to deal with the deluge of plastic waste we are flooding our planet with. Now researchers at the University of Queensland (UQ), Australia have discovered a species of worm with an appetite for polystyrene that could be the key to plastic recycling on a mass scale. Project lead Dr Chris Rinke from UQ’s School of Chemistry and Molecular Biosciences talks about enzymes capable of specifically depolymerizing plastics, his research and the future of biological solutions to degrade plastic waste.

Read here for more about the research project.

Why can plastics not decompose naturally?

Common plastics are synthetic polymers made from petroleum. These polymers are large molecules with strong carbon-carbon bonds, which are difficult to break apart for most microbial enzymes.

How did scientists come up with the idea that enzymes can break down plastic?

Several scientific studies over the last decade have shown that some microbes can survive with plastic as the only carbon source. These microbes pitted thin plastic film with holes, which suggested that they can degrade plastic. Since microbes are tiny chemical factories capable of producing a large arsenal of enzymes, it was predictable that microbes use enzymes to break down these plastics.

And in your specific case: what made you start doing research with the Zophobas morio?

We knew that small insect larvae such as wax worms (1.5 cm) can eat holes into plastic bags, so we speculated that the much larger superworms (>5 cm) are able to munch on plastic and might be able to eat even larger amounts of it.

The superworms were sceptical at first, but after 24 hours they started to explore and eat polystyrene. We didn’t give them any other choice; the polystyrene group had solely polystyrene and nothing else as their food source. In the future, we will explore other plastic types such as polyethylene as well.

How can enzymes break down plastic and what substances remain? How can they be used?

The encoded enzymes that we detected belong to the class of hydrolases. These enzymes catalyse the cleavage of a chemical bond using water and divide larger molecules in the process. In particular, we found homologues to two hydrolases, a lipase and a serine hydrolase. Both enzymes are likely to act on the carbonyl group in the polystyrene molecule, which has been introduced by chemical and mechanical forces such as the shredding and ingesting of polystyrene by the superworm. The result of this enzymatic degradation are styrene monomers which can be transported into bacterial cells and then further degraded to main bacterial metabolites – using two pathways under aerobic conditions, direct ring cleavage and vinyl side-chain oxygenation.

These metabolites can then be used by other microbes to produce chemical compounds of higher value, such as the bioplastics.

Can you describe your research and the results?

We divided superworms into three groups to rear them on their regular diet of wheat bran, on solely polystyrene, and the last group was on a diet without food.

Our major findings are that we:

- confirmed that superworms can survive on a solely polystyrene diet, and even gain a small amount of weight – compared to the starvation control group – which suggests that the worms can gain energy from eating polystyrene. Two-thirds of the polystyrene-reared superworms even completed the entire life cycle, formed pupae and emerged as adult beetles.

- showed that the gut microbiome of the superworms changes on a polystyrene diet. We saw a loss of microbial diversity, suggesting that polystyrene is a poor diet for the worms.

- used a technique called metagenomics to recover all the encoded enzymes from the gut microbiome and found several potential polystyrene-degrading enzymes. This way, we could infer which enzymes and pathways are used by the microbes to degrade the polystyrene.

Can the superworm enzymes only break down polystyrene or also other plastics?

In our experiments, we only investigated polystyrene as worm feed. In the future, we will explore other plastic types such as polyethylene as well.

I estimate we are looking at a five-year time frame to characterise and optimise the enzyme for applications in recycling plants.Chris Rinke

Do you think using the enzymes from the superworms in recycling facilities will be economically feasible? If so, how long will it take before an appropriate recycling plant can go into operation?

We envision degrading polystyrene into styrene monomers, using first mechanical shredding and then enzymatic degradation. Styrene can then be further metabolised to a range of bacterial metabolites, e.g. pyruvate. These metabolites can then be used by other microbes to produce chemical compounds of higher value, such as the bioplastic polyhydroxyalkanoate (PHA). For example, engineered Pseudomonas putida strains have been used to produce PHAs for a large number of applications such as biodegradable plastic alternatives and biomedicine.

The timeline depends on the funding. We have currently applied for public funding and are also reaching out to industry partners. I estimate we are looking at a five-year time frame to characterise and optimise the enzyme for applications in recycling plants.

What other projects researching enzymes to recycle plastic are there?

As far as I am aware, research is still going on to further explore the enzymes produced by bacteria in the wax worm guts (see above). There was also a recent discovery of a polyethylene-degrading bacterium from a landfill in Japan, and the identified enzymes have since been optimised in the laboratory.

We have also just begun to expand our search for plastic-degrading enzymes to move beyond insect larvae. We will screen habitats all around the globe, including landfills, rivers and deep sea sediments, for enzymes capable of degrading a wide range of synthetic plastics and bioplastics. We aim to build a library of plastic-degrading enzymes and hopefully some of them will advance to be used in plastic recycling plants.

What role will these enzymatic processes play in the future for dealing with plastic waste or waste in general?

It will take several years to characterise the enzymes involved in plastic degradation, but once we have found the most efficient enzymes, we can offer a biological solution to degrade plastic waste. This biodegradation will be an alternative to chemical recycling methods, which are known to involve toxic products such as toluene, and can be coupled with the production of bioplastics. We envision that this process will incentivise plastic recycling.