Triveni Turbines : Powering the circular economy: Steam turbines transforming waste into clean energy

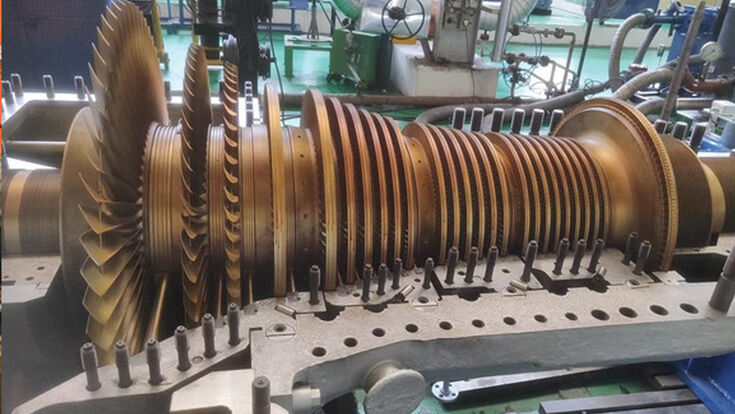

New rotor design.

- © TriveniAs the global energy sector pivots away from fossil fuels, the spotlight is now firmly on renewable and sustainable alternatives. Among these, Waste-to-Energy (WtE) has emerged as a pivotal solution—bridging the gap between responsible waste disposal and clean power generation. Thermal WtE, in particular, converts municipal, commercial, and industrial waste into electricity and heat, reducing the volume of landfill waste while significantly offsetting greenhouse gas emissions.

According to a recent MDPI study, WtE systems in Europe alone have the potential to prevent up to 50 million tons of CO₂ emissions—a compelling statistic that underscores the environmental value of this technology. At the heart of these systems lies advanced steam turbine technology, the driving force that turns thermal waste into grid-ready energy.

The Triveni advantage in WtE innovation

Triveni Turbines, a global leader in the sub-100 MW power segment, is at the forefront of this green energy transition. The company delivers highly efficient, custom-engineered steam turbine solutions designed specifically for the demands of WtE plants, including Combined Heat and Power (CHP) systems. These turbines harness low-pressure steam to deliver electricity and heat, resulting in 14–15% cost savings compared to standalone power generation systems.

By playing a key role in base-load Waste-to-Energy Independent Power Plants (IPPs) across India, Europe, Thailand, and South Korea, Triveni Turbines is helping cities and industries convert their waste streams into sustainable power sources.

Case Study: Greener Paris through WtE in Créteil, France

A shining example of Triveni’s engineering prowess is its recent project in Créteil, France—a mere 20 km from the Eiffel Tower. One of the country’s leading WtE facilities is undergoing a major capacity upgrade to process an additional 100,000 tons of household and medical waste annually, bringing the total to 345,000 tons.

To support this expansion, Triveni was awarded the contract to supply a 28.9 MW steam turbine to replace an aging 20 MW unit. The turbine is designed to operate at challenging parameters—44 bara, 355°C, and 149 TPH—while supplying process steam (16 bara), supporting district heating (7 bara), and exporting electricity to the grid.

Triveni delivered a tailor-made turbine that not only met these multifaceted requirements but also improved energy recovery, reduced carbon footprint, and enhanced overall system reliability. As an end-to-end solution provider, the company managed design, manufacturing, supply, erection, and commissioning—all under one roof.

Case Study: Refurbishing reliability in Turkey

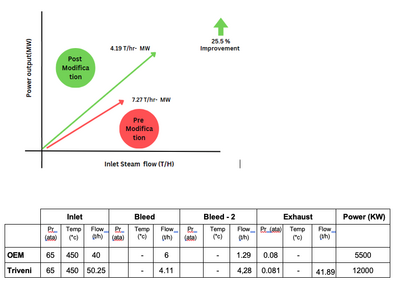

In another impressive showcase of its expertise, Triveni-Refurb took on the challenge of transforming an underperforming 12 MW impulse turbine in Turkey, originally supplied by a competitor. Plagued by vibrations, governor instability, and bearing failures, the turbine struggled to exceed 6.5 MW, falling far short of its intended output.

Triveni’s team re-engineered the turbine, converting it into a high-efficiency reaction turbine by increasing the number of stages from 11 to 25. This required complex modifications to the existing casing to accommodate Guide Blade Cascades (GBCs)—a feat made possible through deep mechanical expertise and precision engineering.

Post-refurbishment, the turbine not only regained its full 12 MW capacity, but also exhibited significantly improved performance, efficiency, and reliability—testament to Triveni’s innovation-driven approach in extending the life and performance of energy assets.

A sustainable tomorrow, today

Triveni Turbines’ contributions to the WtE sector underscore the critical role of steam turbines in the circular economy. By enabling waste conversion into thermal renewable energy, these systems reduce landfill burden, extend resource life, and minimize reliance on virgin fuels.

Looking ahead, the integration of CO₂ capture technologies into WtE plants offers even greater promise. As cities grow and waste volumes rise, energy recovery through efficient steam turbines will become indispensable—not just for sustainability, but for energy security and economic viability.