Recycling : Site Zero: this is the world's largest plastic sorting plant

The world's largest and most modern plastic sorting plant is located in Motala, Sweden

- © Svensk PlaståtervinningAt first glance, the town of Motala, which has a population of around 30,000 and is located on the eastern shore of Lake Vättern, far away from the major cities of Stockholm and Gothenburg, does not seem like the ideal location for the world's largest sorting plant for plastic packaging waste. Yet the town developed into a veritable industrial town with a railway connection as early as the 19th century thanks to the construction of the Göta Canal, which connected the Baltic Sea with the Skagerrak and made it possible to circumnavigate Denmark.

The old industrial hall in the east of the city, where refrigerators and kitchen appliances used to be manufactured under the name Elektrolux before the company moved its production abroad, measures around 60,000 square meters. In the spirit of a circular economy, the extension of life cycles, the industrial hall has been put to a new use: Svensk Plaståtervinning, a Swedish plastic recycling company, took over the hall a few years ago and has now opened the world's largest and most modern plastic sorting plant.

"This plant is one of the first of its kind. It produces first-class material qualities while reducing the ecological footprint," explained Mattias Philipsson, CEO of the Swedish company Svensk Plaståtervinning and operator of the plant. "With innovative technology, Sweden is taking the next step towards a closed-loop economy."

Around 33 per cent of plastic packaging in Sweden is recycled. Nevertheless, a lot of recyclable material is still lost. There is great potential here that we want to utilize.Mattias Philipsson, CEO of Svensk Plaståtervinning

State-of-the-art technology from Sutco

Motala I, a sorting plant that was also built by German plant manufacturer Sutco, went into operation at the same site back in 2019. Thanks to the renewed investment in the site by Swedish recycling company Svensk Plaståtervinning, the current Motala II sorting plant is considered the most modern and largest in the world.

"Around 33 per cent of plastic packaging in Sweden is recycled. Nevertheless, a lot of recyclable material is still lost. There is great potential here that we want to utilize," explains Mattias Philipsson, CEO of Svensk Plaståtervinning.

"Since 2019, we have been successfully recovering four different types of plastic that can be recycled. Today, with the latest technology, we can go one step further and achieve our new goals," Philipsson continues. The company's new goals are "no waste, no downcycling and no emissions".

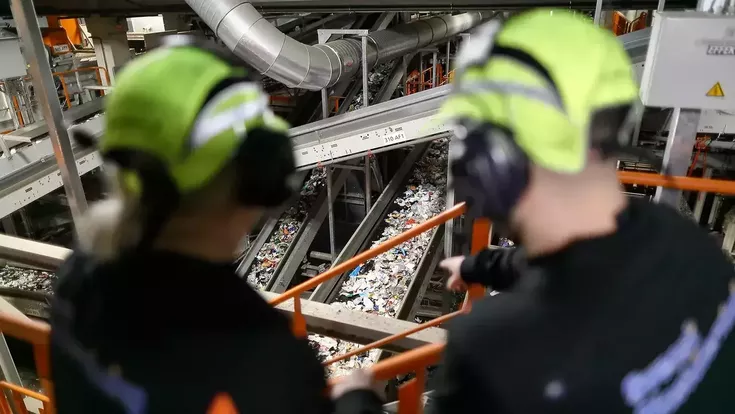

Thanks to 500 tons of steel, countless conveyor belts with a total length of almost five kilometers, numerous infrared sensors, screening drums, ballistic separators, the latest exhaust air technology, intelligent bunker management, fully automatic baling presses, compaction systems and closed loops, the plant is able to process 42 tons of material per hour and recover 12 different types of plastic from packaging waste. This doubles the input volume compared to the first sorting plant, which has been in operation since 2019. Further washing and pelletizing systems are also planned by 2025.

The combination of sorting and process technology enables the collection of twelve types of plastic, so-called fractions, such as PE and PP film, HDPE, PP, colored and transparent PET bottles, PET trays and various types of polystyrene with a very high degree of purity.

According to Mattias Philipsson, the capacity of 200,000 tones of plastic packaging per year that Site Zero can sort - located exactly halfway between Gothenburg and Stockholm and therefore in the catchment area of both major cities - is significantly higher than the total proportion of plastic waste from Swedish households. In order to fully utilize the plant, Finnish plastic waste will also be accepted from 2024.

"With Site Zero, we are doubling our current annual capacity to 200,000 tones. This will enable us to accept all plastic packaging generated in Swedish households in future and ensure that it becomes part of the circular economy again," explains Mattias Philipsson.

Since 2019, we have been successfully recovering four different types of plastic that can be recycled. Today, with the latest technology, we can go one step further and achieve our new goals.Mattias Philipsson, CEO of Svensk Plaståtervinning

Svensk Plaståtervinning - Sweden's pioneer in plastics recycling

With the increasing global focus on sustainability and environmental protection, the recycling of plastics plays a crucial role. In this context, Svensk Plaståtervinning has established itself as a key player in Sweden's efforts to create a greener future. The company has its roots in the Swedish recycling movement, which emerged in response to growing environmental concerns and the need for sustainable waste management.

Svensk Plaståtervinning's main business is the collection, sorting and recycling of plastic waste. Over the years, the company has invested heavily in advanced sorting and recycling technologies - most recently in the Site Zero plant in Motala. The quality and variety of plastic waste can make recycling difficult. The company meets these challenges by continuously innovating and improving its technologies and processes. For the first time, 12 different plastics can be sorted and recycled separately in Motala. In the future, the company will continue to focus on expanding its capacities and technologies in order to keep pace with the growing volume of plastic waste and increase its recycling efficiency.

Svensk Plaståtervinning plays a key role in achieving Sweden's climate and environmental targets. By 2030, Sweden plans to reduce its greenhouse gas emissions by at least 63% compared to 1990, and by 2040, a reduction of at least 75% is to be achieved. Sweden is also committed to increase the recycling rate of plastics. This includes improving the collection, sorting and recycling of plastic waste. Through a combination of legislation, promotion of technologies and public involvement, Sweden is striving to significantly reduce its environmental impact and at the same time promote the sustainable use of resources. Recycling plastics not only reduces the amount of waste that ends up in landfill, but also reduces the need for new plastic products, which in turn reduces greenhouse gas emissions.

Site Zero: 95% recycling rate, 98% degree of purity

"Site Zero is a milestone for Sutco and an important contribution to our vision of a sustainable and efficient circular economy," says Naemi Denz, Managing Director of Sutco Recycling Technik.

Purity levels of up to 98% can be achieved through the combination of sorting technology and a well-thought-out sorting process. The clean material fractions are currently being further processed by recyclers in the European Union. However, Site Zero's long-term goal is to build up recycling capacities to process the main fractions at the site itself. The LVP sorting plant relies entirely on the use of the latest generation of NIR sorting equipment, meaning that manual sorting steps are no longer necessary. The direct further processing of the mixed plastics into high-quality agglomerate products is unique to date. This is ensured by flexible and intelligent post-sorting. This allows the proportion of residual fractions to be significantly reduced. "We are delighted to have such strong and competent partners at our side. The cooperation in our first project has already convinced us of TOMRA and Sutco. It is the quality and flexibility of their systems and the reliable service that have made them our partners. Together, we want to turn Site Zero into a sorting plant that serves as a role model in Europe," explains Philipsson.

At the Motala site, up to 95% of the processed packaging can now be recycled, compared to 47% at the old plant, where only four types of plastic could be sorted. The plastic fractions remaining after sorting are separated and sent for chemical recycling, the production of new composite products or energy recovery with carbon capture and storage. "Together with our customer Svensk Plaståtervinning and the partners involved, we have created a state-of-the-art sorting technology," explained Michael Ludden, CEO of Sutco Recycling Technik. "Site Zero is a further contribution to a functioning circular economy."

We are very proud to have successfully installed this system. It was an exciting challenge, but thanks to our strong team and the good cooperation with our customer Svensk Plaståtervinning, we were able to complete it successfully.Naemi Denz, Managing Director of Sutco Recycling Technik

The European approach to plastics recycling

Plastic production has increased exponentially in just a few decades - from 1.5 million tones worldwide in 1950 to 359 million tones in 2018. Europe faces the challenge of managing the growing mountain of plastic waste. According to a 2020 report by the European Environment Agency (EEA), around 29.1 million tons of plastic waste were produced in the European Union in 2018.

The European approach to plastic recycling is deeply rooted in the concept of the circular economy. In contrast to a linear economy based on the principle of "produce, consume, dispose", the circular economy aims to reuse, repair, recycle and keep resources in the economic cycle for as long as possible. This minimizes the need for new resources and reduces waste and emissions.

The EU is actively pursuing strategies to reduce plastic waste. This includes bans on certain single-use plastic products, the introduction of guidelines for less plastic packaging and the promotion of alternatives to conventional plastics. Initiatives such as the EU Plastics Strategy aim to make recycling processes more efficient and improve the quality of recycled plastic in order to increase its reuse. The development of markets for recycled plastics is also being promoted.

Effective plastics recycling can save significant amounts of greenhouse gases. The production of plastics from fossil fuels is energy-intensive and emits large amounts of CO2.

Sutco - Sorting and processing plant "made in Germany"

Sutco Recycling Technik GmbH is a German plant engineering company specializing in the design and production of plants for waste management. The company, part of the LM-GROUP, is based in Bergisch Gladbach and serves customers worldwide. Sutco develops and builds various types of plants, including sorting plants for lightweight packaging, plants for biological waste treatment and plants for processing substitute fuels. Sutco emphasizes the importance of sustainable and efficient solutions in waste management, with a focus on adapting technologies to specific customer needs.