Advertorial : Lindner at IFAT: Efficient Recovery of Recyclable Materials

Lindner at IFAT: Efficient Ways to Optimise Waste Management and the Development of Plastic Recycling Systems

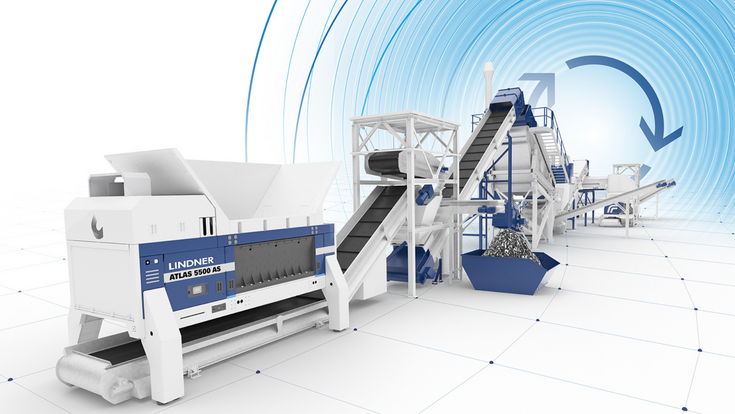

- © LindnerEnergy-efficient and profitable solutions for the challenges of tomorrow's waste management – at the IFAT 2022, hall B6, booth 251/350, and the VDMA outdoor area, recycling pioneer Lindner will present innovative shredders and system solutions that maximise efficiency and output gains and enable waste disposal and recycling companies to successfully enter the field of plastics recycling.

“Make the most of waste” - This motto has been guiding Lindner Recyclingtech’s work for many, many years, and yet it is more relevant than ever. The Green Deal and the associated New Circular Economy Action Plan (CEAP) call not only for the reduction of CO2 emissions, electrification of the economy and greater energy efficiency but, above all, ask for potential secondary raw materials contained in material flows to be better processed and analysed. At the IFAT 2022, hall B6, booth 251/350, Lindner will be showcasing solutions for these industry-specific and future-oriented challenges and will also be presenting ways to obtain and process recyclable plastics.

From zero to hero in plastics recycling

Plastics recycling is becoming increasingly important in waste management. Improved sorting and shredding systems enable potential secondary raw materials – including plastics – to be optimally extracted. At the IFAT 2022, Lindner is reaching out to waste disposal and recycling companies who want to take advantage of Lindner’s extensive, long-standing plastics expertise and actively enter this emerging industry. In addition to its experience in sorting, shredding, and washing, Lindner also offers specific consulting on individual or system solutions and engineering.

Saving energy and increasing output

The future belongs to the electric motor. Energy-saving, they make a valuable contribution to reducing operating costs, saving CO2, and promoting a future with lower emissions. Lindner’s innovative E-models, which are available in both stationary and mobile, offer cost-effective operation with optimised efficiency at all times. The DEX (Dynamic Energy Exchange) is one of Lindner’s signature features and ensures maximum efficiency and consistent performance through its active recovery of braking energy. Compared to conventional hydraulic drives, energy consumption can be reduced by up to 40% by actively recovering braking energy during shaft reversing. Continuously high performance also increases the throughput significantly. A win-win through and through.

Higher availability and productivity

Higher input flows alongside a pursuit of increased productivity call for a sustainable, comprehensive, and yet cost-effective solution. At the IFAT 2022, Lindner will be presenting numerous product innovations with simplified maintenance options. The resulting higher availability, combined with lower maintenance needs, also counteracts the industry’s general shortage of skilled workers.

New Urraco 4000 with e-drive

As a special highlight, the Urraco 4000 is Lindner’s new mobile machine generation and will be presented at the IFAT outside area. Electric drive, separately operated crawler tracks and ease of maintenance all included.

It’s what the industry and politics are calling for – conservation of our resources, reduction of CO2, and electrification of the economy. Lindner provides the answer to the most urgent demands in the waste and recycling industry with its Urraco 4000. Bridging the gap between the tried-and-tested longstanding models Urraco 75 and Urraco 95, this model is particularly impressive with its optional plug & play e-drive. The tracked chassis powered by its own independent power unit makes it easy to take the shredder to its destination, quickly plug it in and start operation. Facilitated accessibility to maintenance areas and the drive ensure shorter downtimes and improved productivity while maintaining high output. Moreover, the proven twin-shaft system combined with the optimised material intake shreds bulky and high-volume materials with ease. Thanks to the model’s extended operation area, feeding by a wheel loader is possible at any time. The Urraco 4000 can be used for materials as varied as waste wood, bulky waste, C&I, C&D, light scrap, and much more.

MEET LINDNER AT IFAT 2022:

30 May – 3 June | Munich, Germany

Hall B6, Booth 251/350

Outdoor Area: VDMA Demonstration Days Biomass