Sirmax Group at Fakuma 2024 : 60 years of history and a focus on green products for the automotive sector

Upcycling for automotive interiors

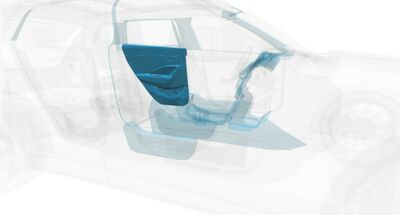

Fakuma, one of the most significant trade fairs for the plastics industry, will take place from 15 to 19 October in Friedrichshafen, Germany. It will be an opportunity for the Sirmax Group to showcase its latest developments in sustainable materials for the automotive market, particularly for aesthetic interior components such as door panels. Sirmax already supplies a range of certified products on an industrial scale, containing between 10% and 30% post-consumer recycled material, depending on the application and specifications required. These products have successfully passed all internal laboratory tests and have been validated to meet the standards of leading European OEMs and Tier 1 suppliers. This is just the beginning of the Group's upcycling journey in the automotive sector. Sirmax aims to further increase the recycled content in its compounds, with ongoing developments to reach 40% and the potential for a further increase to 50% of the total.

The aim is to promote the transformation of waste materials and the conversion of polypropylene from urban selective collection into a new generation of high-performance compounds through the development of an advanced production system. This is the aim of the "Aurora" project, developed in collaboration with the University of Padua, La Sapienza University of Rome, Ghent University in Belgium and Smart Mold, the spin-off of the University of Padua specialising in technology and research in injection moulding, in which Sirmax holds a 50% stake.

Sirmax is bringing two products to Fakuma that effectively combine high performance, reduced environmental impact and flame retardancy, with a focus on sustainability, efficiency and safety in the automotive sector: A V0 class self-extinguishing ABS (1.5 mm) and a V2 class self-extinguishing PS (0.8 mm), both exemplified in applications such as charging stations for electric vehicles. Available in both traditional and round versions, these products contain a percentage of pre-consumer recycled material and are free of antimony trioxide (ATO), which is typically added to halogenated self-extinguishing compounds to suppress, reduce and delay flame propagation. The range also includes 5 VA certified halogen-free PC/ABS designed for electrical applications.

In line with its commitment to sustainability, the Sirmax Group has recently obtained several certifications. One of these is the CSTB QB certification for its Xelter S TPEs, which are used for window profiles and seals in the construction sector. The Xelter S family of thermoplastic elastomers has successfully passed physical, chemical and resistance tests, confirming its high elastomechanical properties, excellent weather resistance and durability over time.

Also significant is the Yellow Card HB certification obtained for Sirmax's entire range of round compounds. These include Green Isofil®, Green Isoglass® (PP filled) and Green Isoter® (ABS), which contain post-consumer polypropylene. This certification, issued by UL, the independent US certification and safety agency, evaluates the flammability of plastic materials following specific laboratory tests. Sirmax is one of the first companies to receive the certification for such a wide range of materials, including unfilled polypropylene, mineral filled (calcium carbonate/talc) and reinforced (glass fibre or mixed fibre/talc) variants, with PCR recycled content ranging from 10% to 99%.

60 years of success and a look to the future

The Sirmax Group celebrated its 60th anniversary in 2024 with an event at its headquarters in Cittadella (Padua, Italy) attended by many local institutions, including the President of the Veneto Region, Luca Zaia, the Member of the European Parliament, Elena Donazzan, the Regional Councillor for Economic Development, Roberto Marcato, and local leaders of Confindustria. The event was an opportunity to announce a new three-year industrial plan. The company is reaping the benefits of investments made over the past four years, totalling €180 million, including internal growth with the doubling of facilities in the US and Poland, a 10% increase in production capacity in Europe, and acquisitions in recycling (S.E.R., now Sirmax New Life) and bioplastics (Microtec, now Sirmax).

The new industrial plan for 2025-27 includes investments of €30 million, following the multi-country, multi-product strategy outlined by Massimo Pavin, President and CEO, and focusing on expansion into foreign markets. The objectives include the completion of the Group's 14th production site in Hosur (India) by 2026, which will complement the two existing sites in India, as well as the expansion of the Anderson site in the United States.

"Our strength lies in our diversification, both geographically and in terms of products," said Massimo Pavin, President and CEO of Sirmax. "In addition, our localised value chain consists of short supply chains directly in the regions where we operate internationally. This allows us to mitigate the impact of geopolitical issues, shipping costs and tariff policies. At present, the business is sound and has excellent growth prospects in overseas markets where we anticipate further investment. The Fakuma will be a valuable opportunity to showcase all our initiatives, particularly in the area of sustainability, in which we believe and in which we are investing heavily, both in our products and in our corporate policies.