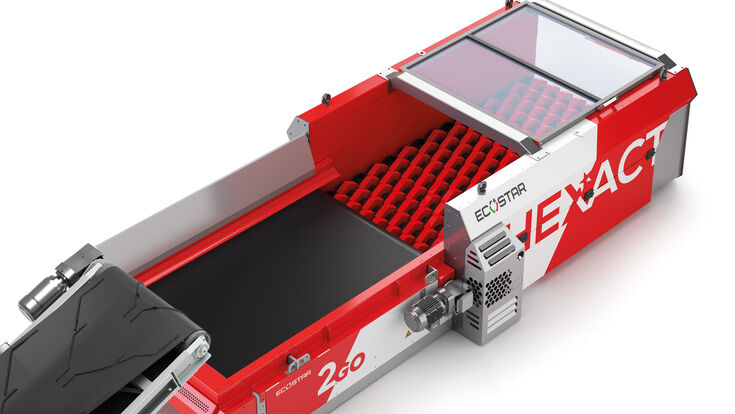

Ecostar introduces the 2GO conveyor belt : The feeding conveyor belt especially designed for the Hexact stationary screen

Whatever the incoming material, it can be introduced through a loading belt that can be either aligned with the 2GO belt or arranged crosswise with respect to it. The 2GO conveyor collects the material from the loading belt and succeeds in distributing it uniformly on the Hexact screen at the right speed and from the correct height.

2GO conveyor belt was specifically designed to prevent excessively forceful or quick introduction of the material on to the Ecostar stationary screen which, when very abrasive or heavy, can have an effect on the duration of the screen discs or the on the correct operation of the shafts. Moreover, the new Ecostar conveyor belt reduces system design time and increases material screening quality, as the entire screening surface is exploited.

To efficiently manage the different materials being screened with the stationary disc screen, the 2GO conveyer belt is also equipped with a speed adjusting system.

With a 2,462mm length, 1,803mm width, 854mm height, and weighing 1t, 2GO is very compact and easy to install and is compatible with the Hexact range – from Hexact 2000 to 10000.

At Ecomondo, Ecostar is exhibiting the 2GO conveyor belt in line with the Hexact 2000 stationary screen, a system known for its compactness, high quality-screening, reliability, low maintenance and best performance with materials and waste such as organic, wood, MSW, plastics, multimaterial, metals, C&D, C&I or RDF and more.

The Hexact stationary screen has been the preferred screening solution for operators worldwide, being able to treat even the most difficult materials in the most adverse conditions, thanks to the patented Dynamic Disc Screening (DDS) technology with which is equipped. More than 400 stationary screens stand proof, working in recycling plants globally by standing alone or in line or in loop with shredders, windshifter or bag opener machinery.

About Ecostar

Ecostar is synonymous with the most advanced and refined technology in the mechanical separation of waste and recyclable materials since 1997. The research and development made by Ecostar have created personalized solutions for every type of material to be screened. Thanks to the patented Dynamic Disc

Screening technology, today many types of waste can be efficiently used to supply clean fuels and energy sources, such as biomass and RDF, or substances useful for agriculture and forestry, such as compost. Headquartered in Sandrigo – Italy, Ecostar is present in 49 countries around the world.