Energy from Waste : Heat recovery from Compost: A new green Energy Source

How did you come up with the idea to extract heat from compost?

Right after my college education, I started working with a farm near Syracuse, New York, and we started a composting facility, which was the first in the New York region to accept food scraps. I was amazed by how much heat the active compost piles produced with good formulation and management. This was something I pursued for my own interest with a number of farms in the Finger Lakes region of New York, but I never implemented anything – until my wife and I relocated to Vermont, when I was hired in 2004 by a farm owned by Terry and Joanne Magnan, who were trying to improve their manure management. I was able to work with them to fund, design, build and operate a compost aeration and heat recovery facility. We brought in some different partners, including AcroLab, a company based in Windsor, Ontario, which had proprietary heat exchange technology. Within their company they had a division called Agrilab Technologies, which was doing research and development on heat transfer from compost. We were their first commercial installation. When it didn’t work out with an international partner to become a direct business partner with the company, they licensed us the technology and we used the same name – Agrilab Technologies – to start a Vermont-based business.

Can you describe how your technology works and what is necessary to build a facility like this?

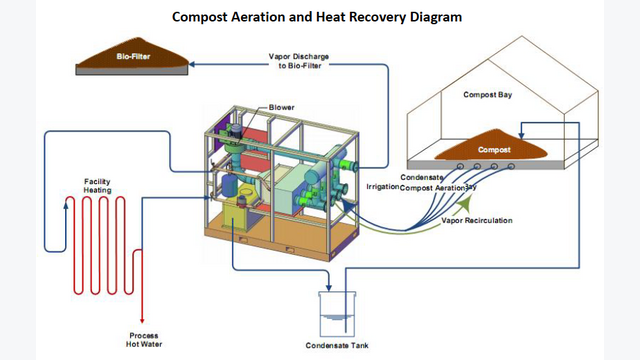

First of all you need a good compost process. If you don’t have a good mixture of feedstocks, carbon and nitrogen ingredients, and you don’t have the right oxygen and moisture levels, it is not going to be a vigorous compost process. Through the process of active decomposition, you get temperatures of 55 to 70°C (130 to 160°F) as a natural co-product of the process: basically those microorganisms are working and sweating off their body heat. Normally this is just steam and evaporation off into the air, a little bit to the ground. By using the negative aeration process, forced aeration is becoming more common in the composting industry; it’s probably more common for people to push air into the compost pile to get in more oxygen and support the process. But there have always been sites that use negative aeration or a kind of vacuum to draw the vapour out of the pile – that’s largely what we do. We use the negative aeration process. We have to insulate the pipes and the ductwork but we pull 150°F moist vapour out of the compost pile, which at the same time pulls oxygen from outside and helps the process. We pump the hot vapour to a specialised heat exchanger and then it’s very similar to a solar-thermal or geo-thermal system. We are not creating electricity; we’re just capturing the renewable thermal energy. And through plumbing, it can be distributed to a wide range of uses: from heating facilities, heating wash water and other heat exchangers to heating dry product or heating greenhouses. Depending on the side needs, there is a range of applications.

Would it be possible to generate electricity?

Potentially. Some companies use high-temperature solar energy to create an electrical current; their temperature ranges are a little higher than what we generate. But that range is getting closer, so we hope to be able to use this energy for low current electricity at some point – maybe power lighting and small motors, but nothing like a biogas or digestion facility.

Could this system also be used not only on a farm level but in a municipality or a small town with a large part of food waste in the mixture?

Absolutely. While our first clients were livestock and dairy farms, we’ve grown into commercial and municipal facilities. We had a pilot project in Boston. And we have a site in Michigan that handles commercial and municipal materials, grass, wood chips and food scraps. We also have a few other sites that include food scraps in their mixture. Any biodegradeable material can be used, although the formulation may need to be adjusted slightly.

How small and how big can your facilities be?

We have a standard product line that is well suited to medium and large sites. Our equipment is modular, however, so each unit will basically put our mechanical equipment in a 20-foot shipping container, or on a metal skit frame – those units can handle anywhere from 2,000 to 12,000 cubic yards per year. Conversion to tonnes depends on how dense the material is, but maybe half as many tonnes on average.

At larger sites we would have multiple units. We have a site in Middlebury, Vermont; at the site in Michigan, there are multiple units. The largest site handles around 100,000 cubic yards a year. Our equipment handles a portion of that, so we might be handling 20,000 to 25,000 cubic yards through our compost aeration system. It’s just a modular approach – a number of windrows or cells to meet the site’s capacity.

In terms of the smallest scale, we are still doing some prototyping on small insulated containers for people who have a horse farm, for example, or for a rural community with a smaller volume. They are just coming into commercial use. But of course, with the bigger piles there is a lot more energy to use, so that is where our initial focus is.

What about input and output?

I would start by saying it’s variable – the compost process is variable anyway. But it also depends on how the energy is being used in terms of the heating load. The easiest typical summary is to say 1000 BTU/hour/tonne of compost being aerated, and you are not aerating a compost pile 24 hours a day. You might even rotate four different batches of compost. You do need quite a bit of compost to make it a viable heating source, but there are thousands of facilities in the US and probably globally with that scale of composting. However, it is best suited for medium to large sites of at least a couple of thousand cubic yards per year.

Is it viable to also heat urban areas?

We are doing both. The site in Michigan is right next to Flint, which is a good sized city, so they handle over 30,000 cubic yards of material per year. Many cities would be of that size or even larger. It would just be a matter of whether they needed 4, 8, 16 or 32 windrows of capacity, how much thermal energy they need, and if they are able to get it into the district heating system to circulate to nearby offices, commercial buildings or residences. That’s absolutely possible; it’s just a matter of how you distribute the hot water, water and glycol mixture.

How much investment is needed to install a facility?

That really depends on what infrastructure is already at the site. What we call our “frugal Yankee farmer model” – just the very basic approach with the gravel pad outside – might cost 150,000 dollars. For a site that needs a lot of concrete and drainage and a building cover, it could be half a million dollars. It also depends on how many modules you need. With a large municipal facility, you might need a couple of million dollars for the equipment and site improvements.

Beyond selling the equipment, we help people plan out what they would need in terms of piping, working pads, electrical and data connections – things of that nature. We have a consulting side to the business to help people know ahead of time what to expect.

In terms of the smallest scale, we are still doing some prototyping on small insulated containers. But of course, with the bigger piles there is a lot more energy to use, so that is where our initial focus is.Brian Jerose, Agrilab Technologies

What possible revenues are there?

Every business model is unique, of course. But most of the more successful sites I see try to get more of their revenue from compost sales rather than their tipping fees for inbound materials. In terms of the heat, it is most cost-effective to use it immediately on site just because of laying that plumbing. We have examples of sites that are right next to another thermal energy user: a building that is on the adjacent property to a compost site could be able to use that thermal energy.

I would say the first benefit for most of our systems is the process efficiency. We are saving people labour, accelerating the process and operating more material on a smaller footprint, and then the heat recovery is another layer of value. With the colder northern sites, we are able to help people maintain wintertime operations by using this heat in the process. But then we also build facilities that have a bigger heating load, for their offices and shops and greenhouses, or drying product before they run it through a sifter in the spring.

There are different kinds of pinpoints for different customers that we try to direct their thermal energy for, as well as helping them make their composting process more efficient.

Is there a difference between the amount of heat in summer and in winter?

Yes, on some level there is less heat in the winter. Particularly through negative aeration, you could be pulling in 0°C air or colder on a cool day and that could mean the compost pile is not as hot. But if you build large compost piles that are three metres tall by four metres wide, they may be cold on the outer edge but they are self-insulated to some degree, so you still have that 65°C (150°F) in the core even with a pile that is covered in snow.

You can over-extract, absolutely. That is part of why we monitor the system for temperature and oxygen levels and flow rates. And if it appears that we are cooling off a pile, we slow down the fan speed or shorten the length of the aeration cycle.

How labour-intensive is it to maintain a facility?

Broadly speaking, it is less labour-intensive than turned windrows. A lot of our customers would originally be turning the windrows with a big payloader or other type of turning equipment, and then add our aeration system to speed up their process and reduce labour. That said, you still need a lot of labour for mixing and handling the materials. Sites are as small as a single operator with some of our farm sites, while some of our bigger facilities have 20 people. But this is for a number of tasks people do. Managing the system is like a batch process; an average retention time is four weeks. It depends on production goals and the size of the site, but controlling the settings is just a matter of looking at temperature and oxygen readings and maybe adjusting the fanpower or timer slightly.

Some of our customers hire us to do remote assistance. This means I can sit bundled up here in our job trailer and see what is going on in Michigan or Massachusetts or elsewhere in Vermont where we have clients. Some of the clients operate the system entirely on their own after we provide them with start-up support, while other sites continue to hire us every month to optimise their systems, so we have different ongoing support models.

Are there similar systems on the market?

The compost aeration side is offered by a number of companies in the composting field. There are some good long-established companies like Green Mountain Technologies and Engineered Compost Systems, which build medium and large facilities that include aeration. We are unique in the fact that we have commercialised the heat recovery side of it – that’s our claim to fame, I suppose; we are able to improve the composting process but also get some additional value for heating shop buildings, water and so forth. We add another layer of value.

Are there disadvantages to heat recovery from compost?

Only if you overcool your material. Some of the original technology around heat recovery involved physically running coils of pipe in a compost pile. You can imagine that wasn’t very practical for a site handling thousands of yards of material. That process can also cool off the compost and diminish the controlled decomposition. So our approach of just using the heat from the vapour combines the best of both worlds and that’s where we think we are getting ahead. So yes, you need to pay attention not to overcool the pile. It’s avoidable but it can happen.

Heat recovery from compost is a relatively new technology and still very rare. Why do you think that people are somewhat reluctant to adopt it?

I have a few theories about this. One is that we are based in small rural Vermont and we haven’t had a huge sales and marketing effort. We are still a relatively small company, even though we’ve had a good growth phase.

Looking at the technology development curve, even though we had success at a couple of early sites, it has taken a few years to find out how to successfully integrate this technology and find reliable components that are up to harsh operating environments. Our initial target market was the dairy and livestock industry, which has seen an unfortunate downturn in milk prices in the US in the last few years, so our original target market was not in a spending mode as we were ramping up. Fortunately we have brought it into that commercial and municipal space and we now have more sites in more states, and are hopefully getting more recognition. We were able to present at the national composting conference in Texas this January. So I think we are getting more exposure and having meaningful conversations with bigger facilities. Hopefully we won’t be such a small topic, but you have to educate the market. Your early adopters have to be willing to take a bit of a risk. Now that we have sites with multiple years of good operating history, those conversations with new customers are easier.

Do you think there can be a global market for heat recovery technology?

Absolutely; we’re having conversations with people in Kenya, Norway and Australia, for example. We’d love to be able to get into an international market. But we’ve had to be strategic about what markets to pursue and make sure we have local partners to help install and maintain systems. There are not just energy shortages; a lot of sites are facing labour shortages and space constraints if they’re operating in an urban area. „So facilities need to operate more efficiently and with less labour.“

About Brian Jerose:

Brian Jerose is co-founder and President of Agrilab Technologies Inc., a Vermont-based company building and servicing composting and heat recovery systems for farms and commercial/municipal facilities. Brian has over 25 years of experience working on composting and sustainable development projects. He has an MS in Environmental and Resource Engineering from SUNY College of Environmental Science and Forestry in Syracuse, New York. www.agrilabtech.com