Electronic Waste : Dutch researchers develop method to separate plastics from e-waste

From automotive parts to consumer electronics and medical devices, electronics are increasingly being integrated with plastics to form a seamless unit with the product. On the surface, this is a win-win situation, resulting in lighter, more aesthetically pleasing and cost-effective products.

But look closer and you will see that this integration makes recycling and repair more difficult. In this way, it works diametrically against the circularity of products.

Researchers around the world are trying to find solutions to this problem. A new disassembly method that allows electronics to be removed from the carrier at the end of a product's life, thus enabling recycling and repair, has now been developed by the Dutch technology research institute TNO. According to the researchers, this innovation contributes to future efficiency and cost savings in business, while reducing CO2 emissions and electronic waste. Initial research has recently been published in the Journal of Cleaner Production.

Printed electronics on the rise

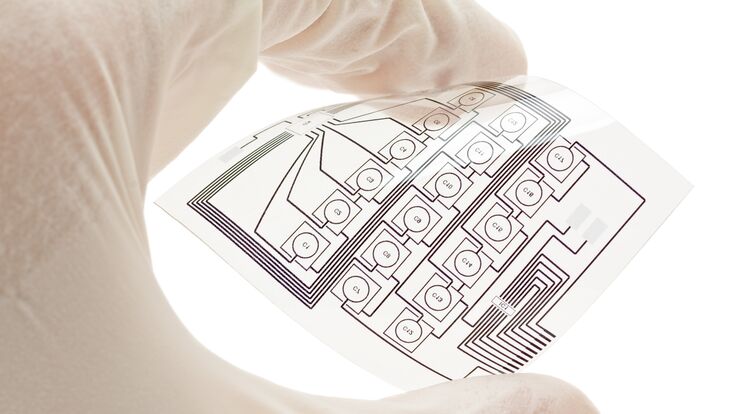

Because printed electronics can be seamlessly integrated into almost any product, companies are increasingly turning to them. There is no need for mechanical buttons and switches; they are printed. This means the electronic part weighs less and looks better. Production is also easier and faster. Applications include wearable medical sensors, car dashboards, aircraft control panels, industrial machinery, washing machines, and coffee machines. It is estimated that the market for this technology will grow from around $175 million to more than $3 billion between 2022 and 2032.

Related article: Global e-waste flows monitor 2022

Recycling challenges

The technique involves fusing electronic components and printed metal with plastic to protect the electrical circuit. But: as a result, it is virtually impossible to repair or recycle. Currently, shredding and incineration are the only options for this type of electronics at the end of its life. This results in CO2 emissions and unnecessary loss of raw materials. Only one-fifth of the world's electronic waste is currently properly recycled. The amount of e-waste is estimated to reach 74.7 million tonnes by 2030 and 110 million tonnes by 2050.

Related article: Canada's e-waste generation tripled in two decades

Water-based layers

But now the Dutch research institute presents a solution to this problem: For the disassembly of this printed form of electronics, TNO has developed a special water-based layer. These were applied between the printed circuitry and the outer plastic layer of the electrical tester. Tests showed that the layer was strong enough to withstand up to 85% humidity and a temperature of 85 degrees Celsius for 1000 hours. Simultaneously, the new layer is flexible enough to remove the plastic without damaging the electronics. When products were found to be defective during testing, they were taken apart and repaired. The plastic was then reapplied and the electronics worked as they should.

The process allows printed electronics to be repaired and entirely recycled. In the past, this was not possible because the electronics were fused to the plastic. This will allow companies to repair design errors during production, leading to cost savings and more efficient use of materials. In addition, it will improve recycling, reduce waste and enable more sustainable production methods. Companies will be able to bring new products to market that are already compliant with the European Commission's upcoming Ecodesign for Sustainable Products Regulation.