Battery Recycling : New global Partnership for Battery Recycling

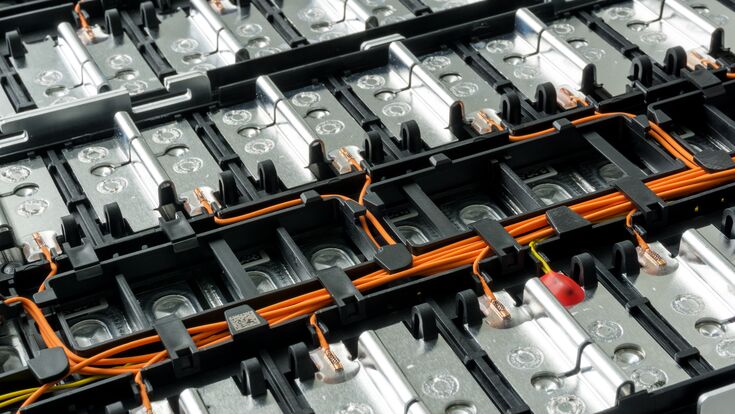

As mobility is becoming more and more battery-driven – many countries plan to allow only emissions-free cars in the near future – the need for specialized recycling facilities rises as well. The battery recycling market offers huge opportunities. Many companies already gearing up to profit from this highly lucrative market.

Recently Canadian company Li-Cycle, an industry leader in lithium-ion battery resource recovery and the leading lithium-ion battery recycler in North America, and Vines Energy Solutions (“VinES”), a Vingroup company that specializes in the research, development and manufacturing of advanced batteries for mobility and energy storage applications, announced the launch of a global recycling partnership. Vingroup is the largest private conglomerate in Vietnam.

Under the new partnership, the companies are exploring global recycling solutions for VinES and VinFast, a global electric vehicle manufacturer that is also part of Vingroup. The new partnership is expected to support VinES and VinFast in their creation of a closed-loop battery supply chain to enhance their environmental goals.

In addition to a significant manufacturing complex in Vietnam, VinFast has announced plans to build a large EV manufacturing facility in North Carolina in March 2022. VinFast was granted an incentive package of $1.2 billion from the State of North Carolina and expects to invest $2 billion to build the project’s first phase, which is designed to have capacity of producing 150,000 vehicles per year.

Commercial demand for Li-Cycle’s patented and sustainable lithium-ion battery recycling technologies is growing steadily. The Company currently has four operational Spoke recycling facilities in North America with a total processing capacity of 30,000 tonnes per year, or the equivalent of batteries from approximately 60,000 EVs. Based on Li-Cycle’s current project pipeline, the Company expects to have a total of 65,000 tonnes per year of lithium-ion battery material processing capacity in North America and Europe as Li-Cycle continues to scale its Spoke & Hub network to support the recycling needs of a growing customer base.