About 15 years ago a livestock farm in Vermont (USA) installed the world’s first commercial-size composting facility that turns excess heat into energy for the farm. Diamond Hill Farm uses the compost aeration and heat transfer system of Vermont-based company Agrilab Technologies to capture the metabolic heat produced by microorganisms during aerobic composting through a negatively aerated fan system (read the interview here). The hot compost vapour is then blown against the heat exchange system to heat water for radiant floor heating, feed preparation and sanitation of equipment. “The only disadvantage is the potential to overcool your material, so you have to pay attention,” says Brian Jerose, co-founder of Agrilab Technologies.

The farm served as inspiration for a project at the University of New Hampshire (UNH). The university turned its Organic Dairy Research Farm (ODRF) into a model farm for energy independence and nutrient management, where the installation of a composting facility with heat recovery addresses the manure, nutrient and energy issues in an integrated approach.

The process is called aerated static pile/heat recovery composting (ASP/HRC). In contrast to the most common composting processes (static pile, passive composting systems let the materials decay slowly without being turned; passively aerated systems use windrowed piles that need to be turned frequently), the ASP approach does not require turning. This also means it reduces labour and fuel costs. Because of the aeration, the compost process is accelerated.

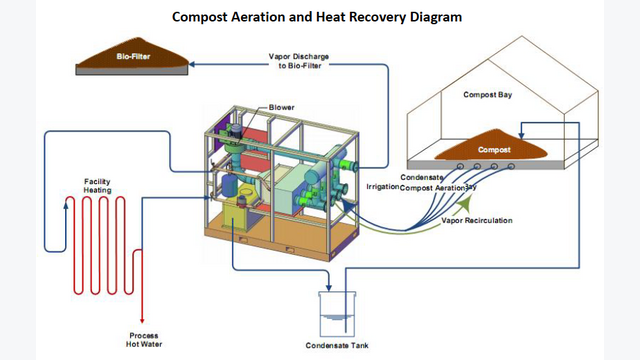

In an ASP/HRC system, the organic wastes are loaded onto a concrete floor with embedded perforated pipes. These are connected to a manifold system. This either draws air down through the decomposing feedstock (negative aeration) or forces air up through the material (positive aeration). In negative airflow applications such as the one at the ODRF, the process creates a contained airflow of heated vapour that can be directed through a heat exchanger and/or biofilter to reduce odour and other pollutants. This means the vapour captured in an ASP system is a potentially harvestable source of heat energy. At the ODRF it is used to heat water. About 1.4 MMBtu of heat energy is generated per tonne of material.

(Want to know more about how the technology works, read our interview with Brian Jerose here)

Apart from compost sales as a source of income, the on-farm used heat results in reduced energy costs, as Prof. John Aber, who set up and led this project, explains: “Diamond Hill Farm used the heat to warm a heifer barn and reports saving $10K on energy and earning $10K on the sale of the compost.” As for the UNH project, he sees the possibility to build a low-cost facility that can be paired with high tunnel greenhouses on campus.

For Aber, heat recovery from compost is a real alternative: “The technique is relatively new, and I think is often confused with anaerobic composting for methane, which has yet to prove financially viable, in my opinion,” he says. “There has been much federal money in the US spent on anaerobic processes, which really will only work on very large farms. Sometimes I think this aerobic composting for heat energy is too simple and too low-tech to get much attention. Financially, though, I think it can be a winner.”