Biomethane : Power to Gas with biological methanisation: German researchers focus on new biogas upgrading method

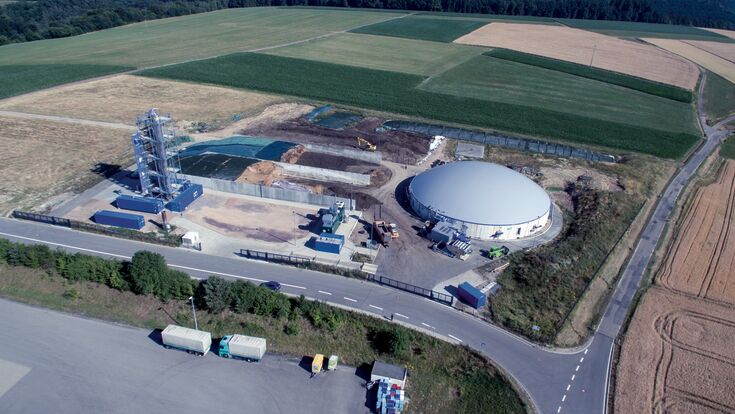

The biological methanisation on the left (the two towers) and on the right the biogas plant whose raw gas is used for methanisation.

- © PFIIt took a war, but finally the whole world seems to be in a rush to find reliable alternatives to fossil fuels. Biomethane, also known as Renewable Natural Gas (RNG) is amongst the prime contenders.

Biomethane is the upgraded form of biogas. Since raw biogas produced from digestion is not high quality enough to be used as a fuel gas for machinery, the proportion of methane must be increased. In a biogas upgrader, the methane in the biogas is concentrated to the standards of natural gas (CNG), from about 40 to 60% to 98 to 99%. Carbon dioxide (CO2), hydrogen sulphide (H2S), water and contaminants such as dust, oil and aerosols are removed.

Like our content? Subscribe to our newsletters!

Biogas Uprading Methods

Biogas upgrading methods can be categorised as follows:

- Membrane separation

- Pressure swing adsorption (PSA)

- Amine scrubbing

- Water wash (or water scrubbing)

Another promising method is biological methanation. The upgrading process developed by the Research Facilities Department at the testing and research institute PFI Germany (Prüf- und Forschungsinstitut Pirmasens) does not remove CO2 from the biogas, but adds hydrogen and converts it to methane with the help of archaea (primordial bacteria). In the next step the gas is desulphurised via activated carbon and dried via an adsorption dryer. The nutrient medium and water are recovered via a sophisticated recycling system.

The pilot plant in the energy park of the city of Pirmasens has been feeding biomethane into the city’s natural gas grid since the end of 2016. However, the system still needs to be optimised for broad market entry.

Stefan Dröge, Head of the Biotechnology Department at the PFI, talks about the biological methanation method and what's necessary for a broad market entry.

How long has research into biological methanation been going on at the PFI?

We have been active in this research field since 2012. Initially, in cooperation with the University of Mainz, we looked for suitable microorganisms for biological methanation and found what we were looking for in thermophilic biogas plants. We then worked on the development and optimisation of suitable bioreactors and bioprocess technology.

Could you explain what biological methanisation is and how it works?

Biological methanation makes use of the ability of certain microorganisms, so-called methanogenic archaea, to form methane from carbon dioxide and hydrogen. In most process engineering approaches, including that of PFI, these microorganisms are cultivated in a special bio-reactor that is charged with the source gases. These are biogas from running plants (agricultural BGA, waste fermentation plants, digesters), which typically contains between 35 and 50 % CO2 as raw gas, and green hydrogen from electrolysis plants powered by renewable electricity. In the reactors, the hydrogen with the CO2 content of the biogas is converted into methane by the production organisms. The biomethane can be fed into the natural gas grid or used as fuel in the form of CNG.

How did the researchers come up with the idea for this method?

From a certain share of fluctuating RE generators (wind, solar) in electricity generation, technologies for long-term energy storage are needed to a considerable extent, this has been clear for a long time. For such long-term storage (especially seasonal), Power2Gas processes are the obvious choice. Since we have been active in the fields of process-biological and process-technical optimisation of biogas plants for more than 15 years, we were driven by the question of how the existing plants could be integrated into a long-term storage strategy based on P2G. This led to the idea of developing special reactors for biological methanisation as a sub-component of P2G plants.

What are the advantages over established biomethane production processes?

In conventional biomethane production, the CO2 content of the raw biogas is split off by physical or chemical processes and released into the atmosphere. P2G processes with biological methanisation make it possible to use this CO2 fraction for additional biomethane production and, via the connected electrolysis plants, to simultaneously absorb surplus electricity from RE plants and use it in an economically viable way.

What is still necessary for a broad market entry and by when do you expect this to be possible?

So far, several factors have stood in the way of a broad market entry. With RES shares in the electricity mix <50%, surplus electricity is only available irregularly and to a limited extent. Due to the legal regulations (feed-in priority and fixed electricity tariffs), electricity from plants still operating under the Renewable Energy Sources Act (EEG) is generally too expensive or not available for the operation of P2G plants. Against the background that natural gas was available in large quantities and very cheaply until the beginning of this year, the development and construction of capacities for biomethane production have not been a particularly high priority for both industry and politics. However, due to the accelerated expansion of renewable energy plants and the current gas crisis, the situation has changed considerably and we are already seeing a significant increase in demand from industry and the energy sector for P2G solutions. This means that the framework conditions for a broader market entry are now in place.

Are there other biogas upgrading/biomethane production methods that will be researched at the PFI in the future?

We see our expertise in the areas of biogas and biological methanation and will continue to focus on these technologies.

To your knowledge, are there other projects worldwide that are looking at new methods for biomethane production?

Regarding Power2Gas processes with biological methanisation, Germany is clearly a pioneer, especially in terms of developing and optimising the technology. However, there is also increased demand for such plants from abroad.

About Stefan Dröge: Stefan Dröge is a microbiologist and holds a PhD from Johannes Gutenberg University Mainz. He has been at the PFI since 2007, initially as a research assistant in the Bioenergy and Fermentation department. He has been head of the Biotechnology Department since 2013.

Focus of activities: Biogas and Power2Gas, development of fermentation processes and bioprocess engineering, fermentative extraction of biobased chemical feedstocks based on residues.

This article was first published on 6 September 2022.