E-Mobility : Battery recycling: an industry taking the driver's seat

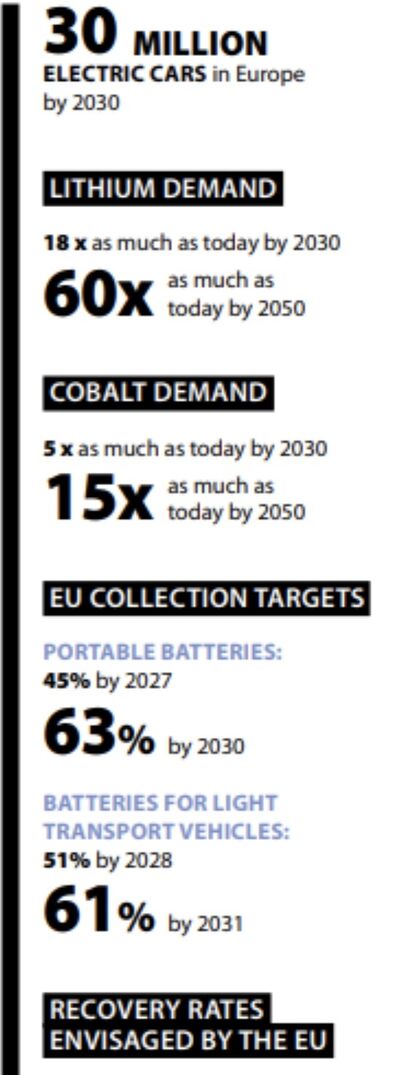

That sounds promising: according to estimates by the European Parliament, there will be around 30 million electric vehicles on Europe's roads by 2030 - mainly cars and two-wheelers, but also an increasing number of lorries. The major goal of the European Green Deal to reduce transport-related greenhouse gas emissions by 90 per cent by 2050 is therefore a good deal closer. But there is also a downside to this ambitious plan: if the millions of e-vehicles announced are actually to become a reality, battery production will have to increase by a factor of almost twenty over the next few years. It is obvious that the waste industry and legislators are already thinking about how this will affect the future European circular economy, material flows and their recycling.

With its updated EU Battery Directive, the European Parliament has provided a number of guidelines. Firstly, the directive creates a new classification by introducing a separate category of batteries, namely batteries used to power light road vehicles such as e-bikes and e-scooters. The EU Parliament argued that the increasing importance of these batteries for e-mobility makes this step necessary, as in future, batteries for light vehicles as well as those used to power heavy vehicles such as cars, ships or aeroplanes will have to show their carbon footprint and contain a minimum proportion of recycled material. These requirements should also apply to industrial batteries with a capacity of more than 2 kWh.

Suggested Reading: Alles zum Batterierecycling (german).

Ambitious quotas.

While the requirement to use certain quantities of recycled material in certain types of batteries already creates a strong pressure to recycle, the European Parliament's idea is to increase this pressure by imposing stricter collection targets. The new directive therefore also provides for the collection target for portable batteries to be increased from the current 45 per cent to 63 per cent in 2027 and 73 per cent in 2030. For batteries from light transport vehicles, 51 per cent is to be achieved by 2028 and 61 per cent by 2031. At the same time, minimum quantities were also set for the recycling of lithium, cobalt, copper, lead and nickel from batteries.

However, battery recycling is increasingly becoming an indispensable necessity, even beyond legal regulations. In the area of battery construction alone, eighteen times as much lithium will be needed by 2030 as today, and sixty times as much by 2050. The demand for cobalt will increase fivefold by 2030 and fifteenfold by 2050.

The industry is generally open to the regulatory requirements that it will have to fulfil in the future in order to obtain at least some of the required raw materials through recycling. Emeric Malefant, Head of the Electric Vehicle Batteries Recycling Programme at Veolia, says: "We support the new regulations. However, there are still some unanswered questions, in particular how the introduction of these regulations can be organised in such a way that it promotes the recycling of batteries in the best possible way." Julian Proells, Director Business Management Battery Recycling at BASF, is also fundamentally in favour of the updated Battery Directive. "It ensures that all players within Europe operate under the same conditions."

Market in a discovery phase.

At the same time, it is clear that the market is currently in a discovery phase. On the one hand, there are currently no large quantities of vehicle batteries that could be recycled - most batteries from electric cars, bikes and scooters will only reach the end of their life cycle. On the other hand, there is also currently a lack of capacity to recycle larger quantities. Most of the recycling plants in Europe are only pilot projects; scaling them up to a commercially viable level will be the next step.A study by the German Fraunhofer Institute for Systems and Innovation Research has put the existing capacity for battery recycling in Europe at 33 kilotonnes per year in 2021. At the same time, the study suggests that the volume of lithium-ion batteries and battery components to be recycled across Europe will increase to up to 300 kilotonnes per year by 2030. By 2040, the figure will be 1,500 kilotonnes per year.

Battery recyclers are still far from sufficiently equipped to handle such quantities, even on the logistics side. This is confirmed by Robert Sommer, Senior Segment Manager at Dolav, an international logistics equipment provider: "Everyone knows that large quantities are coming, but it is still a matter of preparing for the future, of investing in it."Unresolved technology issues.There are also a number of technical issues that still need to be resolved at every stage of the recycling process. On the one hand, it is clear that automation will be unavoidable in the dismantling of batteries as soon as volumes increase. On the other hand, many of the batteries currently installed in vehicles are not particularly suitable for disassembly by a robot, for example because they have flexible parts that are difficult for a robot arm to grip. Regardless of this, automated disassembly also raises many safety issues: from the leakage of hazardous substances to the risk of fire. The best way to design disassembly robots in such a way that they can process as many types of batteries from as many manufacturers as possible is also still an open technical question.

Zied Shakrun, Business Development Future Markets and Innovation at Siemens, is nevertheless convinced that automation will find its way into battery recycling, despite all the uncertainties that still exist: "Digitalisation and automation are the tasks that lie ahead. The potential we see here is huge."Focus on black mass.Many of the developments currently being researched in the field of battery recycling relate to the steps following the dismantling and shredding of used batteries. Shredding is usually followed by treatment of the shredded material, in which steel, aluminium and copper components are separated, leaving behind a mixture of electrode materials, binders, additives and residual electrolyte components - the so-called black mass. It is particularly valuable in terms of reuse, as it contains cobalt and lithium, among other things. However, extracting the two from the black mass so that they can be reused is anything but trivial.

Related article: EV Battery Recycling: Baby, I can recycle your car!

With current recovery technologies, recovery rates of forty to fifty per cent are achieved for lithium, for example, and up to eighty per cent should be possible in the medium term. But even if ninety per cent were to be achieved: After just a few cycles, more than half of the original lithium would have been lost. After a few more cycles, only traces would remain. "This illustrates very well the problem that arises with all recyclable materials that are not one hundred per cent recyclable. Even with high recovery rates, the material loss is very quickly so high that you can hardly speak of a cycle," says Stefan Freunberger, who conducts research at ISTA, the Institute of Science and Technology Austria. Batteries made from organic material.At present, however, recyclates can only cover a very small proportion of the demand for raw materials for battery production anyway, as high demand is offset by only small quantities of batteries that are recycled. However, according to estimates by the Fraunhofer Institute for Systems and Innovation Research, it will still only be possible to cover forty per cent of the demand for cobalt with recyclates in 2040, but only around fifteen per cent for lithium, nickel and copper.

Research has therefore been endeavouring for some time to design batteries that can do without problematic and scarce raw materials and that use organic material. In addition to better availability, such batteries also have an advantage when it comes to recycling. Even if not every organic material is equally degradable, organic materials are generally easier to recycle.The researchers led by Stefan Freunberger have found a solution in which organic material can be used to produce a battery that achieves similar energy densities to lithium-ion batteries based on iron phosphate. Lithium-ion batteries are used in many areas, including e-mobility, where the even more energy-dense nickel-manganese-cobalt cells are also used in the high-end segment.Subsequent utilisation of electric car batteries.The potential for utilising batteries based on organic materials is huge. They are already being used in stationary applications where space is not a limiting factor. With a solution that achieves the energy density of lithium-ion cells, their use in e-mobility is also conceivable in the medium term.Aside from new technological solutions, one way of dealing with the high demand for batteries could also be various reuse concepts and using batteries for as long as possible. The German start-up Battery Lifecycle Company (BLC), a joint venture between recycling specialist TSR and logistics service provider Rhenus, has developed this idea into an interesting business model.

According to Lukas Brandl, Managing Director of BLC, the aim is to act as a service provider at both the beginning and end of a battery's life cycle. Batteries that are irreparably defective and no longer fit for use are deep-discharged and dismantled. Subsequently, the newly founded joint venture also wants to identify high-performance components from old batteries and use them as replacement modules for repairs and in the refurbishment of battery packs.Extended life cycle."We aim to offer comprehensive battery recycling along the entire value chain and want to take over all processing steps from initial testing to repair and dismantling," explains Brandl. Initial testing plays a particularly important role in this concept, as functional batteries whose performance is no longer sufficient for use in vehicles are prepared for reuse in new areas of application. Maximilian Fichtner, Professor of Solid State Chemistry and one of the leading battery researchers in Europe, also emphasises that it makes sense in terms of sustainability to focus on reuse. After all, batteries that are no longer usable in a car can continue to be used for years to come: "They can be used for other purposes, for example as storage media for electricity from wind turbines and photovoltaics. They have more moderate working conditions there than in a car and can continue to work well for another ten to fifteen years before they have to be scrapped or recycled."

Related article: “The construction of appropriate EV battery recycling facilities should begin now”