Compost odour emissions : 10 questions about odour emissions control at composting plants

1 How and where are odours in composting facilities generated?

Generally speaking, odours are gaseous chemicals emitted into the air from a wide range of sources. Some of them are considered pleasant, others not so much. Facilities treating biowaste – anaerobic digestion or composting – manage the process of decomposition. This process inevitably generates odours that fall in the less pleasant category. Even with proper operation and plant equipment, odour will be perceived.

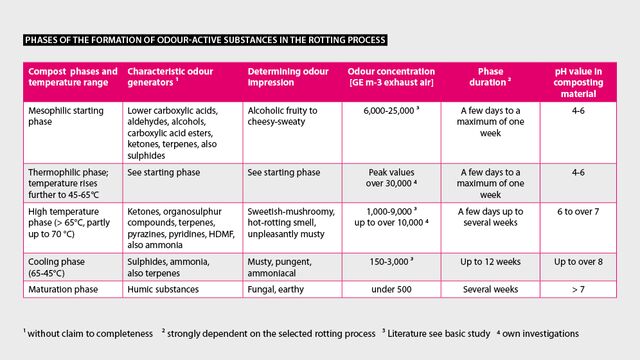

A classification made into five rotting phases of different duration is based on the odours typically produced in these phases. It therefore deviates slightly from the usual division of the rotting phases.

Like our content? Subscribe to our newsletters!

2 How can odour emissions be measured?

The implementation of measurements is regulated in different ways in different countries. In Austria it is regulated in the State of the Art of Composting (Lebensministerium, 2009).

“According to the state of the Art of Composting, guideline values for the limitation of odour emissions may only be set in compliance with the limits of olfactometric measurement technology,” says Melanie Waltner of the Austrian Compost & Biogas Association. “Therefore, it is necessary to first interpret and evaluate olfactometric measurement data.”

The determination of the odour threshold with the help of test persons (DIN EN 13725 ‘Air quality – Determination of odour concentration using dynamic olfactometry’, 2003) is an objective measurement method (ISO 5492, Sensory Analysis – Vocabulary).

Response fluctuations of three dilution levels are generally to be expected in a single measurement (12 measurement series, three runs with four test persons) (VDI, 200218). The limits of the 95 % confidence interval differ by a factor of 3 for repeated measurements by the same laboratory, so that with a ‘true’ mean value of, for example, 300 GE m-3, even 200 or 450 GE m-3 would still be acceptable measurement results. When comparing different laboratories, larger scatter ranges are to be expected (factor 4), so that in this case the confidence limits may differ by a factor of 2.

Two approaches can therefore be considered when setting emission levels:

- mean value

- upper limit of the 95% confidence interval.

3 What impact does process control have on odour generation and what does good process control involve?

According to the state of the art of composting (Lebensministerium, 2009), the possibilities of affecting the biological process through active rotting for the purpose of odour reduction are:

- targeted mixing of the source materials

- control of the rotting temperature

- control of the water balance

- sufficient oxygen supply to the rotting material.

Odour emissions occurring in the subsequent rotting process can be influenced advantageously as early as the preparation and mixing of the input materials. Thus, by optimising the available air pore volume, the oxygen supply to the microorganisms responsible for the decomposition processes and thus the process speed can be increased. In addition, this prevents development of anaerobic zones in the compost. With simultaneous improvement of the structural stability and regulation of the moisture content of the raw compost by mixing different wastes, this goal is considered as achievable in practical operation. Although these measures result in increased costs for plant management, these are far outweighed by the advantages of the improved process flow and the reduced emission potential.

More on composting: Heat Recovery from Compost

Temperature control of the decomposing material is desirable for several reasons. Firstly, overheating the decomposing material to temperatures above 65/70°C leads to a more pronounced narrowing of the species spectrum among the decomposing microorganisms and thus to a slowing down of the decomposition process. The overheating process also releases abiogenic odorous substances with high odour intensity in addition to the biogenic metabolic products that are increasingly expelled from the rotting material.

Limiting the temperature in the thermophilic phase of composting is possible – with a given material mixture – by forced aeration, changing the windrow cross-section or adding water.

If the material mix is unfavourable (biowaste/protein/sewage sludge proportion is too high), this can lead to a higher odour load in the first three to five weeks (depending on the processing intensity) due to larger exhaust air flows or increased turning. On the other hand, since sufficient aeration is also necessary to minimise emissions of climate-relevant gases, regular mechanical turning is indispensable, especially as the heap height increases, regardless of any forced aeration that may be present.

Depending on the process, more intensive irrigation must be very precisely adapted to the rotting body, the respective process phase and the structural stability of the material, as waterlogging, especially at the bottom of the windrow, can lead to anaerobic zones.

An optimized water balance is important for the attainable rotting progress. At the same time, it is important to avoid excessive amounts of waste water for emission reasons. Leachate and condensation water are not insignificant sources of odours, as are anaerobes caused by excessive water content. In this context, both the metered addition of water and the collection and discharge of vapours (surface condensate) and leachate are important.

Particularly in technical plants, a drying cabinet or other equipment for water content determination for the preparation of water balances and for rotting monitoring favour optimised composting operation with minimum odour emissions. Without sufficient oxygen supply to the rotting organisms, the aerobic composting process comes to a standstill. Based on this premise, all measures that keep the oxygen content in the rotting material at a high level are initially advantageous. From the point of view of the highest possible reduction of odour emissions, however, there are serious differences. A balanced moisture regime is also an essential prerequisite for proper hygienisation

More on compost heat: Heat recovery from Compost: A new green Energy Source

4 What are the optimum composting conditions?

Figure 3 shows the optimum composting conditions.

5 What are the current legal requirements for odour control from composting within the EU?

Practice of large composting plants: Industrial Emissions Directive (IED Directive; Directive 2010/75/EU).

6 Are there different standards in different member states?

Yes. In Austria for example, VDI 3475 is currently often used to assess odour emissions. This is a standard from Germany, which, however, does not correspond to the Austrian plant standards (in Germany: predominantly closed composting, green waste composting; in Austria: open windrow composting). For this reason, a standard is currently being prepared in Austria.

7 What are the proven technologies for odour emissions control?

See also question 3.

Mitigation measures for odour emissions from open installations (Lebensministerium, 2009):

General ways to control odour emissions from open landfills include

- immediate and rapid processing of incoming waste

- the production of a structurally rich raw material for the rotting process (sufficient supply of structural material for mixing with wet biowaste or sludge)

- rotting management (e.g. regular turning to avoid anaerobic zones in the windrows, limiting the height of the windrows

- depending on structural stability and turning or aeration system)

- clean operational management (regular cleaning of traffic routes, etc.)

- the choice of the time of transfer (e.g. only when the wind direction is favourable).

Technical measures for exhaust air treatment in forced-aeration composting processes

Deodorisation of the exhaust air from composting is a crucial process step in (partially) closed systems. There are basically three process variants:

- biofilters

- bioscrubbers

- biomembrane process.

The common feature of these processes is the microbial activity of organism communities which are able to biochemically mineralise organic and some inorganic exhaust air constituents under aerobic conditions, up to the decomposition products of water, carbon dioxide and heat.

Other purification processes: thermal and catalytic processes

8 What is odour modelling?

Odour modelling, also known as olfactory modelling, is the quantitative prediction or simulation of the behaviour and perception of odours in different environments. It involves the creation of mathematical or computational models that simulate the dispersion, transport and perception of odours in the air.

The overall goal is to understand and predict how odours disperse and interact with the environment, and how humans or animals perceive and respond to different odour sources.

The process of odour modelling involves several steps, which may include:

- emission estimation: determining the sources and rates at which odour-emitting substances are released into the environment

- dispersion modelling: simulating the physical transport and spread of odour molecules in the air, taking into consideration factors such as wind patterns, temperature, humidity and terrain

- chemical transformation modelling: modelling any chemical reactions or transformations that the odorants may undergo during transport, such as oxidation or degradation

- odour perception modelling: predicting how humans or animals perceive and respond to the odorants based on factors such as concentration, duration of exposure and individual sensitivities

- validation and verification: comparing the model predictions with field measurements or experimental data to assess the accuracy and reliability of the model

There are different models for the dispersion calculation of odour emissions:

- emission calculation (GERDA)

Lagrangian particle model GRAL: consideration of terrain, buildings, possibly vegetation, low-wind weather conditions.

9 What are the key factors when planning a composting facility?

According to the State of the art (Lebensministerium, 2009) the location of a composting plant must be checked for the following criteria with regard to emissions:

- distances to relevant buildings (e.g. residential areas, commercial areas, etc.) and uses (e.g. local recreation areas, etc.) in the vicinity

- meteorology with regard to wind conditions (wind direction and speed), inversion weather conditions or other microclimatic peculiarities

- topography with regard to possible cold air runoff and influences of the orography on the wind field.

If measures to limit odour emissions from composting plants are discussed, at least the following boundary conditions should be considered:

- plant throughput

- type of waste processed

- location dependencies (e.g. distance to the next built-up area, meteorological conditions)

- integrated emission reduction, exhaust air purification system

- available measurement technology to verify the requirements.

10 What impact have advanced technologies such as data driven and AI supported technologies on the sector?

Artificial intelligence (AI) can have a number of positive impacts on composting facilities, improving efficiency, accuracy and overall productivity:

- Waste sorting: AI-driven systems can be used to automate the sorting of waste materials. Using computer vision technology, AI can identify and efficiently separate different types of waste, such as organic waste, plastics, metals and paper. This ensures that the composting facility only receives the organic waste it needs, reducing contamination and improving the composting process.

- Process optimisation: By analysing various factors such as temperature, moisture and oxygen levels, AI can optimise the composting process. Monitoring and adjusting these parameters in real time, AI algorithms can help maintain ideal composting conditions, resulting in faster decomposition and higher quality compost.

- Predictive analytics: AI can analyse historical data and environmental factors to make predictions about composting outcomes. For instance, by taking into account weather patterns, temperature, humidity and other variables, AI can estimate the time it will take for organic waste to decompose and produce high-quality compost. Using this information, composting facilities can better plan their operations and effectively manage their resources.

- Plant maintenance: Composting facilities can use AI for predictive maintenance. By collecting data from sensors and monitoring equipment performance, AI algorithms can identify potential problems or anomalies in real time. This proactive approach allows maintenance teams to address issues before they lead to equipment failure, minimising downtime and optimising plant operations.

- Quality control: AI can facilitate quality control processes by analysing compost samples for various parameters such as nutrient content, pH levels, moisture content and microbial activity. By automating these analyses, AI can provide fast and accurate assessments of compost quality, ensuring that it meets industry standards and regulatory requirements.

- Energy optimisation: AI can help improve energy consumption in composting facilities. Through analysing energy usage data and identifying patterns, AI algorithms can suggest ways to reduce energy consumption, such as adjusting equipment operating schedules, optimising heating or aeration processes, and identifying energy-efficient alternatives.