Plastics Recycling : “Recycled plastic is virtually all around us”

What is the definition of mechanical recycling?

The Waste Framework Directive defines recycling as “any recovery operation by which waste materials are reprocessed into products, materials or substances, whether for the original or other purposes. It includes the reprocessing of organic material but does not include energy recovery and reprocessing into materials that are to be used as fuels or for backfilling operations.”

Under mechanical recycling, also referred to as physical recycling, this involves the processing of plastic materials without altering their chemical structure. Instead, they are subject to a series of steps that alter the physical form of the materials, like grinding and melting. These steps purify the material without breaking the polymeric chains.

Which technologies are used in mechanical recycling?

Mechanical recycling processes differ depending on which polymer is treated, the waste stream it comes from and the intended end application to be produced with the recycled materials obtained.

However, the most representative process includes technologies which firstly shred the input material into smaller fragments, called flakes. These fragments are then washed in designated tanks and during that same process the material is separated based on the distinguishable densities of different polymers.

Depending on the intended use, the washed flakes can be directly converted into new plastic products. Otherwise, the material is further processed via extruders, where material is melted, filtered and lastly granulated into pellets.

For high-quality end applications, recyclers will often include additional sorting steps in their facilities or introduce specific washing and decontamination conditions. The latter is important when recycled materials are used in products intended to come into contact with food.

Since when has plastic been recycled?

The plastics recycling sector has grown alongside the plastic industry. It started in the late 1980s as in-house, post-industrial (or pre-consumer) waste recycling. Shortly afterwards, the first recycling plants emerged to reprocess post-consumer waste, specifically PET bottles.

The technology that was used at that time did not allow for the use of recyclates in closed-loop applications. However, after two decades of research and innovation, technological upgrades allowed for high-quality recycling, enabling the use of recycled plastics even in food-grade applications. Since then, continuous innovation and improvements have led to increasing growth. Recycling technologies have enabled an effective substitution of virgin plastics in a vast array of products.

Want to stay up to date on our content? Subscribe to our newsletters!

How has the technology developed over the years?

Today, the sector that was once heavily labour-intensive and limited to manual sorting is fully automated.

Notable improvements in the quality of sorted waste can be observed with the introduction of optical and sensor-based technologies (like near-infrared (NIR), mid-infrared (MIR) or hyperspectral imaging). With NIR, for example, plastics can be sorted in more refined streams. This in turn decreases the number of unwanted materials and contaminants, allowing for a higher quality of recycling input.

In terms of recycling machinery, significant developments include hot-wash practices, finer filtration, more efficient extrusion machinery and other innovative practices like odour elimination.

What sort of plastic can be recycled mechanically?

Since recycling first started, the number of waste streams suitable for recycling and the end markets have been continuously growing. The biggest waste streams in Europe include household, agricultural, commercial, industrial, building & construction, automotive and electrical & electronic sectors.

In these sectors, the most commonly recycled polymers are PET, HDPE, LDPE, PP, PVC and PS.

Given the above-mentioned advances in technologies, virtually all plastic can be mechanically recycled except for heavily contaminated waste, products made with a combination of materials that cannot be separated (e.g. plastic and wood) or products that have been made without considering design-for-recycling principles (plastic made with high concentrations of additives that alter its intrinsic properties).

What sort of plastic can be recycled chemically?

Chemical recycling technologies are highly dependent on quality and quantity requirements for feedstock materials. To produce an output that can be used in high-quality applications, some technologies, like pyrolysis for instance, have stringent input specifications.

Moreover, chemical recycling is a term that represents a number of different technologies and depending on the technology in question, the targeted plastic will also vary.

When it comes to processing, input materials for chemical recycling must undergo pre-treatment steps like in mechanical recycling – which can include sorting, washing, grinding and even extrusion.

Chemical recycling could nonetheless have the potential to further accelerate a circular plastic future if it can treat the waste which cannot currently be mechanically recycled into high-quality plastics.

How much of the plastic waste is recycled in Europe/worldwide?

Of the 29.5 million tonnes of plastic waste generated in 2020, an estimated 35% was sent for recycling in Europe. The remaining waste was either incinerated (42%) or sent to landfills (23%) (Plastics – the Facts 2022).

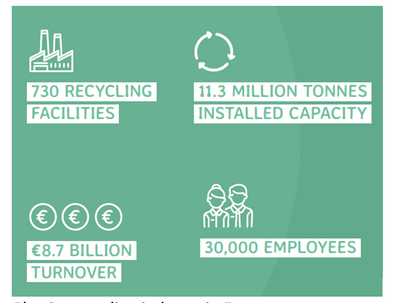

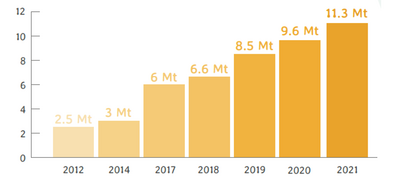

In terms of European plastics recycling capacity, the total in the EU27+3 – where there are more than 730 recycling sites – now stands at 11.3 million tonnes.

Which countries are at the forefront of plastics recycling?

Germany, Spain, Italy, the United Kingdom and France stand out as the countries with the highest installed capacities in Europe. Together, they represent more than two thirds of the total.

Furthermore, in recent years Poland and the Netherlands have stood out as countries with notable growth in recycling capacities.

How can recycling rates be improved?

To effectively address the issue of plastic waste, a holistic approach is necessary – and plastics recycling is just one piece in this puzzle, and a key element in reducing plastic waste. To be effective, it must be successfully implemented along with other solutions.

The first step in this transition is the harmonised uptake of design-for-recycling principles, which would ensure that quality input materials are available on the market. Increased collection, optimised sorting and more efficient recycling processes are equally important. Lastly, boosting incentives for the use of recyclates would fully close the loop and lead to increased recycling rates.

What impact will or would new proposed regulations such as the Packaging Waste Directive, the EU Plastics Strategy and new waste shipment rules have on the industry?

Legislation is an important facilitator of market changes as it creates a pull mechanism for investments and provides legal certainty to the industry players. The targets and measures introduced in the EU Plastics Strategy, Single-Use Plastics Directive, and the Packaging and Packaging Waste Regulation (PPWR) have the potential to boost plastics recycling and enable a strong market for recycled plastic to be established.

Europe sets itself apart as the leader in sustainable legislative action and with the right incentives, it will continue to stimulate the growth of the recycling industry.

How do you view these regulations?

The legal certainty brought about by legislation has boosted the resiliency of the plastics recycling industry in Europe, especially in light of the COVID-19 and energy crises experienced in recent years.

Moreover, legislation is a key factor in creating a positive environment for increasing investments and in parallel it harmonises the approach that the industry can take towards achieving the set goals.

Legislation is an important facilitator of market changes as it creates a pull mechanism for investments and provides legal certainty to the industry players.Antonio Furfari, PRE

Would there be enough recycling facilities in Europe to deal with all the plastic waste generated?

The plastics recycling industry has been expanding rapidly in Europe, with a 33% increase in the last three years alone.

The commitment from recyclers to deliver on the targets is strong. However, increased collection and a comprehensive legislative framework are key to boosting stability on the recycling market and give way to the increased investments that are necessary to ensure continued growth of the industry.

What impact did the pandemic have on European recyclers?

When the pandemic first hit, a number of recycling facilities were forced to cease production. In addition, waste collection across European regions decreased due to workforce shortages, which eventually led to shortages in supplies. All of this put the profitability of the recycling sector in jeopardy.

On a positive note, the support offered through actions such as the Recovery Plan were instrumental in safeguarding the transition towards a circular economy and ensuring that the attainment of the EU recycling targets is not hampered. This has enabled recyclers to remain resilient throughout the challenges posed by the pandemic and to ultimately overcome the crisis.

How is the market for plastic recyclates developing?

Over the last two decades, technology and innovation have been instrumental in increasing the quality of recyclates. Today, recycled plastic is virtually all around us – in our beverage bottles, food containers, office chairs, coffee machines, window frames, various car parts and more.

A significant push factor in accelerating the uptake of recyclates is, of course, the different recycled content targets introduced via legislation.

To further unlock the full potential of the recycled plastic market, the industry must focus on better design, increased collection, sorting and high-quality recycling paired with the proliferation of closed loop and cascaded recycling. This will positively impact the availability and quality of recyclates on the European market, and therefore their exponential increase in new, high-end products.

To further unlock the full potential of the recycled plastic market, the industry must focus on better design, increased collection, sorting and high-quality recycling paired with the proliferation of closed loop and cascaded recycling.Antonio Furfari

What are the biggest challenges currently faced by recyclers?

The low-quality and limited supply of input materials, coupled with uncertainty on the energy market, are the most challenging factors faced by the sector.

Better management of waste shipments and product imports is essential for the sustainable use of resources too.

However, incentives have been introduced to overcome these challenges and with the target of making all packaging recyclable by 2030, collection targets for certain products and the revised Waste Shipment Regulation, European recyclers can look forward to more certainty on the market.

Do you see competition between mechanical and chemical recyclers?

Rather than regarding them as competing, recyclers believe that achieving a true complementarity of these technologies would enable a further reduction in dependency on virgin raw materials and their associated emissions.

Efficiency and sustainability will be key to determining the processes via which plastic waste should be processed in order to satisfy the required product specifications.

How do you see the future of the plastics recycling industry?

Plastics recycling is part of the puzzle of solving the plastic waste crisis. It certainly cannot play its role alone; instead, it must work hand in hand with solutions like prevention, reuse and design for recycling.

The future growth of the installed capacities will vary depending on the type of waste stream but, taking into consideration the EU recycling targets, these numbers are set to rise substantially. Increasing value chain collaboration and initiatives are also making a significant contribution.

Given all that, the recent positive changes in the market are cause for optimism when it comes to plastics recycling and its future.

As long as Europe is among the leading players in driving a circular economy, the recycling capacity and output are set to grow. Working towards sustainable waste management practices to keep the natural resources in the loop would further secure Europe’s competitiveness and self-sufficiency.